Why steel?

Steel bar grating is the staple of the grating industry, mainly used for flooring applications. With a large list of options, any need can be met.

If you are looking for corrosive resistant material, please check out our Aluminum or Fiberglass products

or

see our Stainless Steel options.

Welded Bar Grating

The most economical choice of steel grating product. This grating is manufactured by an electro-forging

process, welding rectangular bearing bars and cross rods. This welding method provides a positive

fusion of cross rods and bearing bars. The most popular is the 19-4 spacing; with approximately 80%

open area the 19-4 spacing allows for passage of dirt, snow, liquids, air and debris. Welded bar

grating is also available in close mesh ADA conforming spacing for use in public areas. Different

bearing bar thickness can be specified, the most common 3/16" is stocked in multiple depths.

1/8", 1/4" are stocked in limited quantities. Bearing bar thickness is offered from 1/8" to 1/2" to

accommodate any load rating requirements. Universally used in most general industrial plants as well as

commercial buildings; it has a wide range of uses such as walkways, platforms, safety barriers, ventilation grates,

and drainage covers.

Dove Tail Grating

This grating is a system of interlocking, perpendicular bars. It provides a smooth clean look ideal for

architectural applications such as grilles, divers and screens. It is used in the same structural

applications as its welded steel counterpart. It is offered in a range of spacing options from 7/16"

to 1-3/16". Dove Tail grating is not recommended for rolling loads. Instead of welding the joints,

tremendous hydraulic pressure is used to bond the two close-tolerance slotted bars together.

Permanent locking is achieved by forcing the deep cross bar into the notched bearing bar.

Swaged Grating

Swaging is the least commonly used choice of connection for steel bar grating. This grating is similar

in construction to our aluminum bar grating products. Rectangular bearing bars and tubular cross

bars are joined together via the swaging process. This process keeps the material free from the

warping and weld flash inherent in the electro-forging process. This profile offers the same

flexibility as our other mechanically locked grating products as to multiple spacings (including

ADA requirements), bar depths and finishes

Stainless Steel Grating

All forms of light duty and close mesh carbon steel grating are also available in stainless steel (both 304 &

316). Stainless steel is great in corrosive environments and environments that need to keep clean such as

food and chemical plants. Welded stainless steel grating can experience discoloration during the

welding of the crossbars to the bearing bars. Passivation and bead-blasting are available to make the

grating stand out and appear new for years to come. This process also removes the discoloration

caused by welding. Swaged and dove tail options are popular for stainless steel as discoloration

does not occur.

Smooth/Serrated

Connections

Banding

Light Duty

Heavy Duty

38 Space

Thicker bars for heavier loads. Check the load chart to verify which height and bar will work for H20 and forklift rated loads.

Heights marked with * indicate that the 5/16" bar is NOT available.

Heights marked with ** indicate that the 1/2" bar is NOT available.

Height

1"(*, **)

1-1/4"(*, **)

1-1/2"(**)

1-3/4"(*, **)

2"(**)

2-1/4"(*, **)

2-1/2"(**)

3"

3-1/2"(*)

4"

4-1/2"(*)

5"

5-1/2"(*)

6"

Bar Size

1/4"

5/16"*

3/8"

1/2"**

Spacing

2-3/8"

Connection

Welded

Crossbars

2"

4"

Surface

Smooth

Serrated

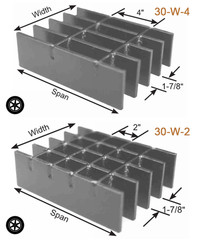

30 Space

Thicker bars for heavier loads. Check the load chart to verify which height and bar will

work for H20 and forklift rated loads.

Heights marked with * indicate that the 5/16" bar is NOT available.

Heights marked with ** indicate that the 1/2" bar is NOT available.

Height

1"(*, **)

1-1/4"(*, **)

1-1/2"(**)

1-3/4"(*, **)

2"(**)

2-1/4"(*, **)

2-1/2"(**)

3"

3-1/2"(*)

4"

4-1/2"(*)

5"

5-1/2"(*)

6"

Bar Size

1/4"

5/16"*

3/8"

1/2"**

Spacing

1-7/8"

Connection

Welded

Crossbars

2"

4"

Surface

Smooth

Serrated

22 Space

Thicker bars for heavier loads. Check the load chart to verify which height and bar will

work for H20 and forklift rated loads.

Heights marked with * indicate that the 5/16" bar is NOT available.

Heights marked with ** indicate that the 1/2" bar is NOT available.

Height

1"(*, **)

1-1/4"(*, **)

1-1/2"(**)

1-3/4"(*, **)

2"(**)

2-1/4"(*, **)

2-1/2"(**)

3"

3-1/2"(*)

4"

4-1/2"(*)

5"

5-1/2"(*)

6"

Bar Size

1/4"

5/16"*

3/8"

1/2"**

Spacing

1-3/8"

Connection

Welded

Crossbars

2"

4"

Surface

Smooth

Serrated

19 Space

Thicker bars for heavier loads. Check the load chart to verify which height and bar will

work for H20 and forklift rated loads.

Heights marked with * indicate that the 5/16" bar is NOT available.

Heights marked with ** indicate that the 1/2" bar is NOT available.

Height

1"(*, **)

1-1/4"(*, **)

1-1/2"(**)

1-3/4"(*, **)

2"(**)

2-1/4"(*, **)

2-1/2"(**)

3"

3-1/2"(*)

4"

4-1/2"(*)

5"

5-1/2"(*)

6"

Bar Size

1/4"

5/16"*

3/8"

1/2"**

Spacing

1-3/16"

Connection

Welded

Crossbars

2"

4"

Surface

Smooth

Serrated

15 Space

Thicker bars for heavier loads. Check the load chart to verify which height and bar will

work for H20 and forklift rated loads.

Heights marked with * indicate that the 5/16" bar is NOT available.

1/2" bar is NOT available.

Height

1"(*)

1-1/4"(*)

1-1/2"

1-3/4"(*)

2"

2-1/4"(*)

2-1/2"

3"

3-1/2"(*)

4"

4-1/2"(*)

5"

5-1/2"(*)

6"

Bar Size

1/4"

5/16"*

3/8"

Spacing

15/16"

Connection

Welded

Crossbars

2"

4"

Surface

Smooth

Serrated

Close Mesh

Stair Tread

Welded Bar Grating is the most common for stair treads, and are widely used for their strength and ease of installation and are universally used in most industrial and commercial applications. All stair treads are custom fabricated to meet the size, width and length specifications of a particular job.

In addition, standard end plates or custom fabricated end plates can be used to meet any bolt hole size or location requirements. Serrated bearing bars can also be used to offer additional slip resistance. Different types of nosing are available to add a definitive visible edge and slip resistance for extra safety.

Steel stair treads are available in light duty and close mesh options.

For a list of available bar sizes, standard widths, and their maximum spans for pedestrian loads,

check out the Load Chart.

Checkered plate nosing is standard, but other options are available upon request.

End plates are standard for stringer connections. Banded or open ends can be done upon request.

See End Plate Details for dimensions.